Error Correction

Error Correction

Types:

- Tape correction

- Chain correction

Tape correction: There are four types of correction of tape.They are given below.

- Temperature correction: This correction is necessary because the tape may be increase or decrease in length due to rise of fall of temperature. The correction is given by the expression

Ct = વ(Tm-To)L

Here,

Ct = Correction for temperature in meters

વ (alpha) = Coefficient of thermal expansion

Tm = Temperature during measurement in degree Celsius

To = Standard temperature in degree Celsius

L = Length of tape in meters

The sign of correction may be positive or negative as the Tm is greater or less than To.

When વ for the steel tape is not given, it may be assumed to be 11 x 10^-6 per degree centigrade of Celsius.

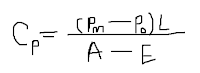

2. Pull correction: During measurement the pull may be greater of less than standard pull. Due to the elastic property of materials, the strain will vary according to the variation of applied pull and necessary correction should be applied. Its expression.

Cp = Pull correction in meters

Pm = Applied pull in kg

Po = Standard pull in kg

L = Length of tape in meter

A = Cross sectional area of tape in square centimeters

E = Modulus of elasticity (Young's modulus)

The sign of correction may be positive or negative as the Pm is greater or less than Po.

When is not given, it may be assumed 2.1 x 10^6 kg/cm^2.

3. Slope correction: It is calculated as below.

|

| Slope correction |

This correction is always negative.

4. Sag correction: This correction is necessary when the measurement is taken with the tape in suspension (i.e. in the form of catenary). It is given by the expression.

|

| Sag correction1 |

When unit weight is given

|

| Sag correction |

Here,

Cs = Sag correction in meters

L = Length of tape in meters

ധ = Weight of tape per unit length in kg/m

W = Total weight of tape in kg

n = Number of spans

Pm = Applied pull in kg

The sign of correction is always negative.

2. Chain Correction: There are three types of chain correction are given below.

1. Correction applied to incorrect length:

True length of line (TL) = (L'/L) x Measured length (ML)

Here,

L = Standard or true length of chain

L' = True length 土 error

Use the positive sign when the chain is too long, the negative sign when it is too short.

2. Correction for incorrect area:

True area = (L'/L)^2 x Measured area

3. Hypotenuse allowance: This is explained in section 1.15.

Hypotenuse allowance per tape = L (secθ-1)

Where,

L - Length of tape

θ = Slope of the ground

This allowance is always added to the tape length.

No comments