Procurement Manual

TABLE OF CONTENTS

Page

1. Executive Summery 3

2. Introduction 4

3. Goals & Objectives 7

4. Discussion 9

5. Execution Works 12

6. Record Keeping 20

7.

Policies for minimum delivery 21

8.

Procurement on Different Cases 22

9.

Materials Name & Specification 25

10.

Conclusion 28

1. Executive

Summery

Procurement

is not a pompous word for buying; Buying is just one part of the procurement

process which spans the whole cycle from identification of needs, through to

the end of a service contract, to the end of the useful life of an asset. It

involves options appraisal and the critical ‘make or buy’ decision – whether to

provide services in-house or to procure services in other ways.

Procurement

decisions based on total cost assessments tend to be more effective than those

based only on cost of purchase and cost of maintenance and repair. Hidden costs

always come back to bite. Making sure that all possible costs are included also

makes for better comparison between suppliers and those looking cheaper at the

outset that make their money after purchase, will then not have the advantage

as before.

The main objective

of the Procurement Department of MACON ENGINEERING is to define a

documented process to maintain proper control and process of all purchasing

activities in order to ensure quality on all procured materials that affect the

quality of the end product, minimizing the cost of the product, growing high

supplier’s loyalty, and satisfy all demand.

2. Introduction

Procurement is the

acquisition of goods and/or services at the best possible total cost of

ownership, in the right quantity and quality, at the right time, in the right

place and from the right source for the direct benefit or use of corporations

or individuals, generally via a contract. Simple procurement may involve

nothing more than repeat purchasing. Complex procurement could involve finding

long term partners – or even 'co-destiny' suppliers that might fundamentally

commit one organization to another.

The importance of procurement is of

strategic importance because it:

- has a

direct impact on the company’s overall expenditure, and the cost of

service.

- directly

affects the company’s delivery of its services

- contributes

to the achievement of corporate, departmental and service objectives.

- provides

a mechanism for delivering key policy objectives, including

sustainability, partnership working, equality and economic development.

- operates

within a complex regulatory framework that must be adhered to.

- is an

area of potentially high risks; It has an impact on service, it has

financial and legal issues and it influences and contributes to the reputation

of the company.

- develops

the role of the company as ‘Community Leader’ particularly in relation to sustainability

and local economic development.

The

principal hallmarks of proficient procurement are:

·

Economy;

·

Efficiency;

·

Fairness;

·

Reliability;

·

Transparency; and

·

Accountability and Ethical Standards.

Economy: Procurement is a purchasing

activity whose purpose is to give the purchaser best value for money. For

complex purchases, value may imply more than just price, for example, since

quality issues also need to be addressed. Moreover, lowest initial price may

not equate to lowest cost over the operating life of the item procured. But the

basic point is the same: the ultimate purpose of sound procurement is to obtain

maximum value for money.

Efficiency: The best procurement is simple and

swift, producing positive results without protracted delays. In addition,

efficiency implies practicality, especially in terms of compatibility with the

administrative resources and professional capabilities of the purchasing entity

and its procurement personnel.

Fairness: Good procurement is impartial,

consistent, and therefore reliable. It offers all interested contractors,

suppliers and consultants a level playing field on which to compete and

thereby, directly expands the purchaser’s options and opportunities.

Transparency: Good procurement establishes and

then maintains rules and procedures that are accessible and unambiguous. It is

not only fair, but should be seen to be fair.

Accountability and Ethical Standards: Good

procurement holds its practitioners responsible for enforcing and obeying the

rules. It makes them subject to challenge and to sanction, if appropriate, for

neglecting or bending those rules. Accountability is at once a key inducement

to individual and institutional probity, a key deterrent to collusion and

corruption, and a key prerequisite for procurement credibility. A sound

procurement system is one that combines all the above elements. The desired

impact is to inspire the confidence and willingness-to-compete of

well-qualified vendors. This directly and concretely benefits the purchasing

entity and its constituents, responsive contractors and suppliers, and the

donor agency providing the project finance. Conversely, a procurement system

that takes the above elements stimulates hesitation to compete, submission of

inflated bids containing risk premia, or submission of deflated bids followed

by delayed or defective performance. Other direct results include collusion in

bribery by frustrated or unscrupulous vendors and purchasing entities, bad

value for those entities and their constituents, and betrayal and abuse of the

public trust for personal gain. In sum, proficient procurement is not difficult

to describe in principle or to distinguish from its antithesis in practice. But

it does require varied professional and technical know-how to establish, as

well as discipline and determination to administer.

3.

Goals and Objectives of Procurement Department:

Procurement

Department has established to co-ordinate the projects and fulfills their

requirements as a part of management and a plan for the Procurement operation.

Procurement Department mainly deals with:

· Materials delivery as per requirement

· Accounting for Materials

· Part of project administration for materials control.

· Departmental Human Resource Development including

Posting, Transfer & Training etc.

The goal and objective of Procurement

Department is to achieve and ensure the above stated points and thus contribute

to achieving the organizational goals as a whole.

Five Rights:

1. Right Time (Construction Period)

2. Right Materials (Considering Quality, Quantity & Cost etc.)

3. Right Price (Minimum Cost)

4. Right Source (Manufacturer, importer, dealer)

5. Right People (H/O + Projects) (ensuring above rights & perfect use)

Standard Operating Procedures (SOPs) of Procurement Department:

1. MPR receives from Project(s)/ Site(s)

2. MPR is authorized by EICs and

Approved by ZICs

3. For Price & Supplier selection –

rate is to be collected and C/S is to be prepared for approval

4. Issue Purchase Order (PO) and send it

to the corresponding supplier.

5. Send a copy of the PO

to the Warehouse before the delivery so that the Construction Dept/ Warehouse

Management could make concerned well conversant about the consignment.

6. Supplier is to submit Bill along with

the received challan copy.

7. After receiving the materials, site

will issue MRR with original challan and send that to the Procurement Dept within

48-hours of the material delivery. MRR will be prepared by Store-Keeper,

Quality checked bay EIC Authorized by ZIC & approved by Head of Warehouse.

8. Challan must be signed by the

Warehouse personnel. If any deviation is there in terms of quantity, it should

be mentioned there.

9. After checking the bill Procurement

dept. forwards the bill to Audit Dept. with supporting (Original MPR, W.O,

Challan with MRR, Bill and approved Statement).

10. After setting the bill by Audit Dept.

forwarded to A/C for Payment.

11. Accounts Department will ensure the

payment timely.

4. Discussion

Scopes and Activities:

Scopes:

The

responsibities or the working scopes of the procurement department of MACON are

as follows:

a) Market analysis and finding the best possible source.

b) Checking and authentication of demand.

c) Searching alternative source to ensure crisis

delivery.

d) Price negotiation in optimum level.

e) Ensuring purchasing using best possible credit line.

f) Establishing healthy supplier’s base.

g) All materials purchasing.

h) All IT materials purchasing.

i) All Electro Mechanical Equipment (EME) purchasing

for all project/Sites & Concerns.

j) All stationary material purchasing for all concerns.

Operational

activities:

The operational activities of the

procurement:

Materials purchase requisition (MPR)

come from the construction site to procurement department twice a month. MPR is

authorized by EIC and approved by ZIC. Procurement department will collect the price

rate of the materials according to the requisition and prepare comparative

statement. At lest 3(three) nos. quotations from reputed suppliers are needed

for the preparation of the comparative statement. The statement is then

approved by the audit department and followed by the Director of the corporate

division. In condition of the approval of the rate, procurement dept. issues

work order (W.O). Supplier deliveries material at site as per W.O. with

original challan. After receiving the material, site personnel issue material

receiving report (MRR) with original challan. MRR will be prepared by

store-keeper, quality checked by EIC, authorized by ZIC & approved by Head

of ICMD. Supplier submits their bill to head office. After checking the bill procurement

dept. forwards the bill to audit dept. with supporting (Original MPR, W.O,

Challan with MRR, Bill and approved Statement). After setting the bill by audit

dept. forwarded to A/C for Payment. Accounts Department will ensure the payment

timely.

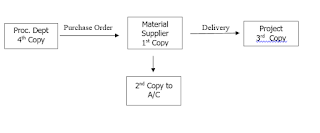

The total

operational activities of procurement dept. of MACON are shown as follows:

5. EXECUTION WORKS:-

Planning Work (Pre Execution):

·

Material Analysis

·

Source Finding

·

Information

Collection

·

Market Survey

·

Negotiation with

Suppliers

·

Necessary formats

Preparation

·

Various statement

& report Preparation

·

Liaison with

other Department

·

Departmental

Meeting arrange and participation in other Departments meeting.

1) Pre-Execution Steps of

Procurement

a. MPR Receive

b. Comparative Statement Approval

c. Work/ Purchase Order Issue

2) post-Execution Steps of

Procurement

a. Delivery Ensure

b. Bill & supporting Challan Receive

c. Enclosures

d. MRR Received

e. Supplier Accounts.

Execution

Procedures of Material Purchase Requisition (MPR)

Execution Flow Chart of MPR

Activity - 01:

MPR is prepared by Project Account at

Project level by the requirement / demand of Project Engineer. A lead-time of

fourteen days is required to deliver / ensure the materials at the sites from

the date of receiving the MPR by Proc. Dept. Project send the MPR to Head

Office through Zonal Office.

Activity - 02

BOQ checking and Brand

selection of the requisite materials are done by the Construction Management

Department (CMD).

Activity - 03

ICMD authorizes the MPR

with:

· Counter checks the quantity with

estimate,

· Searches the existing stock in the

respective Project.

· Decides the necessity of purchasing

or inter project transfer or any others solution for supplying the materials.

The

MPR is finally approved & forwarded to the Procurement Department.

Activity

- 04

After getting approved

MPR, PROCUREMENT DEPARTMENT will give Purchase Order to respective supplier (1st

Copy) and 3rd copy is to send to related project by outgoing box and messenger.

The 2nd copy of PO goes to A/C

dept. and 4th copy is retained at Proc. Dept.

Comparative Statement Approval:

In

case of CS preparation, at lest three quotations are collected from reputed

suppliers. After receiving quotations from suppliers, procurement will deal

with the suppliers for market survey and negotiation. A comparative statement

(C. S) is then prepared. After preparation, the CS is checked and authorized by

the Dept. Head of procurement. Then the CS is forwarded to the internal audit

department for approval of final checking. The CS must be finally approved by

the Director of MACON.

Execution Procedures of Purchase

Order / Work Order:

Execution Flow Chart of

Purchase Order / Work Order

Work Order

Activity – 1

After receiving approved MPR

Procurement Department will issue Purchase Order to the effective Supplier as

per approved rate of Comparative Statement.

Activity – 2

Supplier will deliver the materials

as per Purchase order to respective Project/Site directly and project will

receive the same accordingly.

Activity – 3

After completing delivery of

Materials as per Purchase order respective Supplier will submit Bill to head

office against completed work order.

Please note that, sometimes or in

case of some items make us go through Cash Purchase which does not contain

Purchase Order. In that case, we receive the cash from AFM Dept. and submit

adjustment with necessary documents in time.

Post Execution Stage (After Delivery)

Post Execution Sequence:

a.

Delivery Ensure

b.

Challan &

Bill - Invoice & Supplier Bill

c.

Enclosure - Supporting Documents

d.

MRR - Material Receiving

Report

d.

S/A -

Supplier’s Account

a. Delivery Ensure:

Procurement

Dept. ensures deliveries up to the site. They have to follow up time to time. Procurement Dept. will

ensure the quality and quantity as per our standard and mentioned in CS. Procurement

Dept. will also present at the time of delivery if needed to ensure the

measurement or quality. No inferior quality is allowed to receive by the site.

All materials must meet the quality as ordered.

If there is any problem in

quantity and quality (which noticed later), the site must inform the procurement

department within 24 hours. Procurement department will take the necessary

action for the replacement immediately.

b. Challan & Bill:

The

suppliers submit us bill and receiving copy of delivery Challan for their

payment.

c. Enclosure:

Enclosing papers of Fund Requisition:

The 1st copy MPR or attested photocopy, Triplicate copy of purchase

order, Original copy MRR, Original Bill copy, Receipt copy delivery challan

copy and other supporting documents if applicable.

d. MRR:

1. MRR Prepared by PA/APA after considering

document like MPR 3rd copy, work order, challan and physical

check.

2.

Materials are received by taking proper measurement or weighing where necessary

as the case may be.

3. The project sends two copies of MRR to Head

Office Inventory section with all necessary information (MPR No & Date, PO # & Date, Delivery Challan #, Supplier’s name

& address, Material Quality, Quantity etc). MRR should be sent to head

office within 48 hours from materials receiving.

4.

More than one MRR can be produced

against one MPR but one MRR cannot be produced against more than one MPR.

Without MRR no bill is forwarded to A/C Dept. for payment.

5. MRR should be produced of 3 copies. 1st

copy (white) is sent to Proc. Dept. followed by A/C, 2nd copy (pink)

is sent to ICMD and the 3rd copy (yellow) is sent to Site store.

6. MRR is submitted to Project Engineer for

quality check. After checking and duly signed by Project Engineer, MRR is

authorized by EIC or ZIC in the case of asset type materials. Then the MRR is

sent to ICMD for approval. After proper approval, 1st and 2nd

copies of MRR enclosed with challan are sent to Procurement Dept.

Execution Procedures of Material receiving Report

(MRR):

Execution Flow Chart of MRR

Individual

suppliers account is maintained to keep necessary records of material

purchased, Credit Time, Credit Limit, Total due amount, Billing date, maturity

date etc.

Payment Time:

We use to make payment to our

supplier from Sunday to Wednesday

every week.

Payment Disbursement Sheet:

After payment the accounts dept.

sends a cheque disbursement list against payment requisition, which consists

the suppliers name with FR# and Amount. Then we deduct the disbursed amount

from supplier’s individual accounts.

6. Record Keeping:

Filing works:

1)

Supplier wise

(major material)

2)

Material wise

(major material)

3)

Quotation

/Catalogues

4)

Comparative

Statement (Materials wise)

5)

Work Order /

Agreement / Contract

Other working files:

·

Fresh non

executed MPR

·

MPR with PO (work on process)

·

MPR with Bill/MRR

(payment on process)

·

Other necessary

file

·

Register for cash

purchase

7. Policy for minimum delivery time for materials supply:

The objective of this policy is as

follows: -

a) Submitting the MPRs from the

respective project sites in pre-fixed time (ref. office notice dated 20/1/04)

b) Fill-up the

delivery date column of MPR properly giving the sufficient slack time to procurement dept. as required for

that particular item considering the real situation

c)

All structural phase projects will be allowed to

submit MPR once in a month (i.e. 18-22 of each month)

d) Only

finishing projects (this

will be confirmed and controlled by the respective ZIC & HSC) will be

allowed to submit MPR twice in a month

(10-12 & 18-22 of each month)

e) To update and provide the list of

mobilization projects, structural projects, finishing projects and hand over

stage projects to PD in due time from MACONso that they can plan accordingly.

f) To check & control the MPR

submitting out of the scheduled time (which create extra burden to PD)

g) To check & plan very carefully by

the respective EIC at the time of MPR posting (considering the sufficient stock

during lead time use).

h)

Min. delivery date for 18-22 & 10-12 MPR slot

would be 1st day of next month and 21st day of current

month OR min. delivery time, whatever is maximum to be counted.

i)

Credit purchase is to be preferred in all respect,

expect if the item need to pay in advance.

8. Procurement on different cases:

Electro Mechanical Equipment (EME) materials purchasing:

An all through specification for

specified EME Items will come to Procurement department through EME department

authorized by the HOP, HSC, Head of EME, CSD & Head of Construction.

Procurement Department will deliver the specified requirement to the existing

or promising new suppliers considering brand, origin, company loyalty, previous

dealings with MACON. After collecting the offer EME department prepares

technical comparison. After preparing technical comparison Procurement

Department will prepare financial comparison. Procurement department will seat

with every vendor individually for the price negotiation and to clear all the

issues which may not clear from their offer. The CS will then be checked by

Audit Department, Audit will settle/ negotiate price. Finally the price and

party is approved by the management. WO will issue by Procurement Department.

The suppliers will arrange the

delivery by own up to site. The suppliers will arrange all preparation for

commissioning as per WO. The suppliers will arrange a test run in presence of

correspondent of purchaser.

All payment will make as per the

terms and condition of the WO. All payment will be forward by procurement dept

through a requisition. The bill will be forwarded accordingly with signing of

HOPD, EME Dept. and approval authority. Final bill will also be paid as per WO

with signing of HOP.

Stationary materials purchasing:

Requisition will come from unit

quarterly. HR department (where there is no Procurement personnel) & CPD

will jointly arrange the procurement. Party search, rate collection and CS

preparation will made by procurement department. After proper approval WO issue

and delivery is ensured. Respective HR will ensure the quality and store will

ensure the quantity. Respective HR for cash advance will make a requisition. Adjustment

will be prepared in cooperation of CPD.

Computer & accessories:

Requisition will come to Procurement

Department with proper approval. Procurement Dept will search for the suitable

party. The bidders submit their quotation for the computer. CS will be prepared

by Procurement Department, which is verified by IT Dept to authentic it

technically and approved by the management after auditing. WO will be given by

Procurement Department to the vendor. The IT department will ensure the

quality.

MRR will be prepared by store. Bill

will prepare attaching Requisition, WO, CS Copy, Challan, and MRR. Payment will

be made as per condition. Computer accessories will purchased in cash from a

well known computer market/place. The cash will arrange for the purchase by the

respective HR Dept.

Cleaning Materials Purchasing (for RSL):

Requisition will come from unit once

in a month. Maintenance dept (where there is no Procurement personnel) &

Procurement Department will jointly arrange the procurement. Respective Maintenance

Personnel for cash advance will make a requisition. Adjustment will be prepared

in cooperation of Procurement Department.

Uncommon Item (Special selection for special work):

Requisition will be made with proper

approval. Procurement department will arrange the procurement in consulting

with HOCP. First need to find the source and the available stock. It the item

is possible to arrange in credit facilities than the purchase must be done in

credit facilities with proper audit checking. Procurement department can search

for any substitute or alternate brand to reduce cost.

Urgent basis purchasing:

Requisition will make with proper

approval. Respective Unit will arrange the procurement in consulting with HOCP.

Respective unit will arrange necessary cash for the purchase. If it is possible

by CPD to arrange the materials in short notice by WO placement than will go

through it.

9. Materials Name & Specification

The following matters

are to be followed by Project and H/O relevant personnel during execution:

Main Materials Name &

Specification are to be mentioned clearly for ensuring right material:

1. Cement :

Finest, Dry, Uncrushed packed, as usual color.

2. Rod : Smooth surface, Fresh, Rushed

free, Actual Dia

3. Bricks :

Category - Auto, Semi Auto, and Hand

Made.

: Kinds

- 1st Class, Picket, 2nd

class, Shape, Molding, Metallic sound, Color, Size, etc.

4. Sand:

Sylhet:

Color, 2.5 FM or equivalent (Eye measurement), Coal free & other foreign

materials free.

Medium: Red

or White or Grey color, 1.5 F.M. Coal, Mud, Caker & other Waste Materials

free.

*Both

of the above to be checked by a glass of clean water, Salinity test by tang and

Mud of Mud color.

5) PVC conduit- Wall

thickness (as per sample), Color, Strength, Weight, Flexibility etc.

6) PVC/UPVC Fittings- Color,

Brand, Seal, B/S, Wall thickness, Crack etc.

7) C.I Fittings- Smooth

surface, crake, Hole, Wall thickness, Heavy/Light, Dia

8) G.I Pipe- Brand

seal, Wall thickness, Dia, Thread, Smooth of outer

surface,

Galvanize.

9) G.I. Fittings- Brand,

Good finishing, Smooth surface, Weight, Crake, Thread

etc.

10) Polythene- Color, Thickness, Width, Roll, Crake,

Weight

11) Jute Chatt Length,

Breadth, Thickness, Density, etc.

12) Jute Rope Light/Heavy,

Dryness, Old/New, Weight etc.

13) Door Clamp Flat bar breadth, Thickness, Length,

Weight etc.

14) Door Frame & Shutter Thickness, Length, Breath, Pal, Crake, Hole, Bend

15) Bamboo Dia, Wall thickness (Top &

Bottom), Straight, Light/Heavy, Length etc.

16) Mango Wood Width, Thickness (1/8” under from

delivery challan size),

Straight, Side off free, Length etc.

17) Electric Cable Seal, Insulation, Copper thickness,

Flexibility, Length, Color, Packet seal.

18) Steel Boxes Gaze,

Finishing, Size, Options, Sheet Color, Options perfect

specification, Joint, Grinding, Punch, Lock System,

Channel, Basbar etc.

19) Safety Net Rope-dia, Gap area, Weight, Area (Sft)

20) Marble/Granite/Tiles Thickness, Length,

Breath, Brand Name, Color, Code No

etc.

|

| Flow chart |

10. Conclusion:

From above discussion we can states that the Procurement life

cycle in modern businesses usually consists of seven steps:

a) Information Gathering: If the potential customer does not already have

an established relationship with sales/ marketing functions of suppliers of

needed products and services (P/S), it is necessary to search for suppliers who

can satisfy the requirements.

b) Supplier Contact: When one or more suitable suppliers have been

identified, Requests for Quotation (RFQ), Requests for Proposals (RFP),

Requests for Information (RFI) or Requests for Tender (RFT or ITT) may be

advertised, or direct contact may be made with the suppliers.

c) Background Review: References for product/service quality are

consulted, and any requirements for follow-up services including installation,

maintenance, and warranty are investigated. Samples of the P/S being considered

may be examined, or trials undertaken.

d) Negotiation: Negotiations are undertaken, and price, availability, and customization

possibilities are established. Delivery schedules are negotiated, and a

contract to acquire the P/S is completed.

e) Fulfillment: Supplier preparation, shipment, delivery, and payment for the P/S are

completed, based on contract terms. Installation and training may also be

included.

f) Consumption, Maintenance and Disposal: During this phase the company

evaluates the performance of the P/S and any accompanying service support, as

they are consumed.

g) Renewal: When the P/S has been consumed and/or disposed of, the contract

expires, or the product or service is to be re-ordered, company experience with

the P/S is reviewed. If the P/S is to be re-ordered, the company determines

whether to consider other suppliers or to continue with the same supplier.

____________________________________________o____________________________________________

I think great site for these post and I am read the most of contents have useful for my Carrier.Thanks for these useful information.Any information are commands like to share him.

ReplyDeleteProcurement Management Software

Purchase Management Software

e Procurement Management Software

Procurement Tracking Software

Automated Purchasing Software

Inspiring writings and I greatly admired what you have to say , I hope you continue to provide new ideas for us all and greetings success always for you..Keep update more information..

ReplyDeleteProcurement Management Software

Procurement Management Software India

e Procurement Management Software

BALA VIGNESH, KANI MOZHI

ReplyDeleteI will try

Informative and helpful Article. Really good work. Appreciate it. You might be looking for Smart Purchase Order Management Software in Bangalore

ReplyDeleteVery Nice Blog Post, this article is very nice and useful, Thanks for the sharing. ForBest Contract Management Software for Procurement and Purchasing Visit the website https://thelegalcapsule.com/procurement

ReplyDeleteThanks for the update. I really appreciate the efforts you have made for this blog.

ReplyDeleteContract Management Software for procurement